INTRODUCE ABOUT THE COMPANY

PHAM GIA PHAT ONE MEMBER CO., LTD was established in 2007 with a team of specialized and highly trained employees and employees, modern and synchronous investment equipment with the goal of specializing in manufacturing products. Domestic replacement of imported products. Manufacturing company provides the market with quality products, reasonable prices, best customer service. Products are manufactured on quality management system - ISO 9001-2015.

OUR PRODUCTS

- Wedge wire sieve

- PolyUrethane plastic

- Industrial springs

- Knitting and screening mesh types

- Punch net, filter plate, filter impeller ...

- Industrial valves of all kinds.

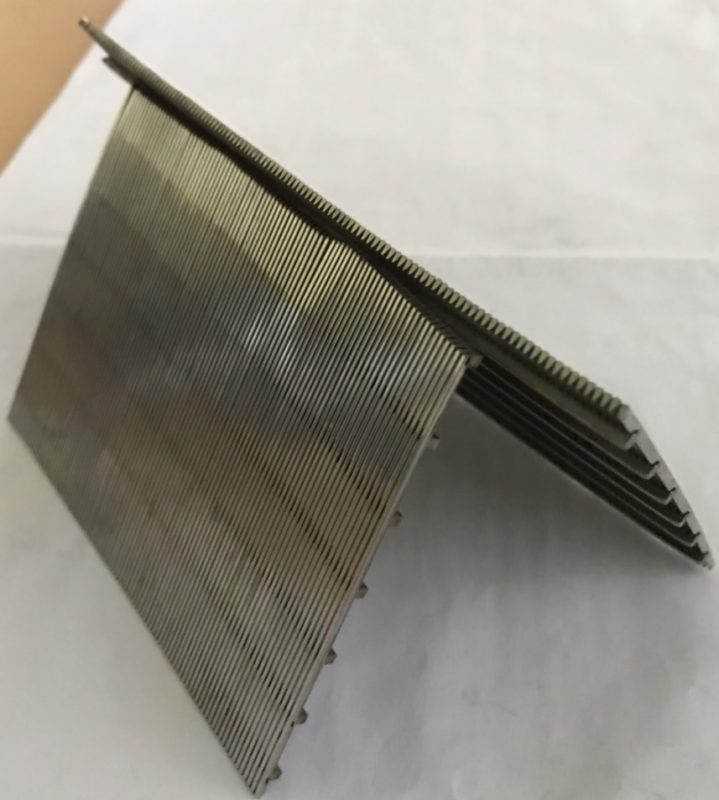

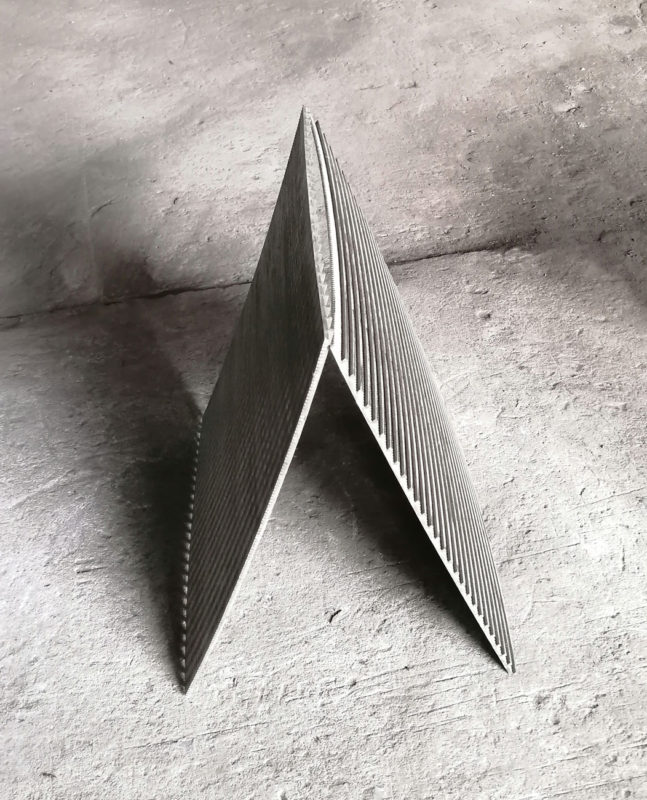

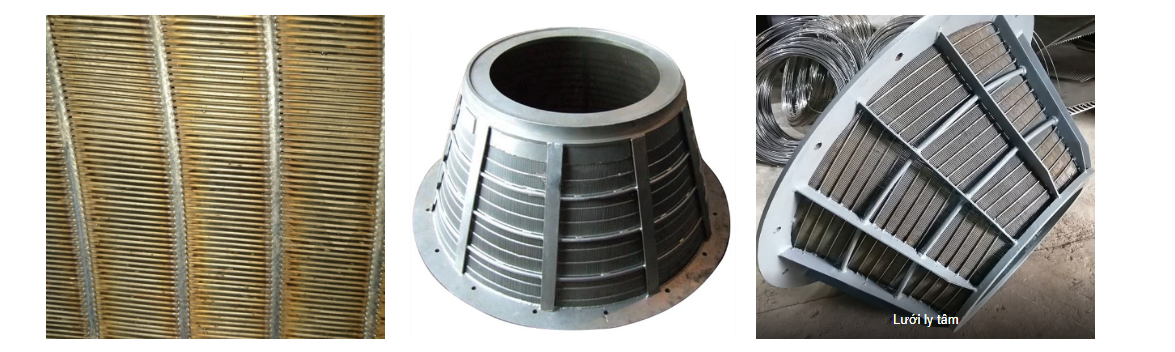

1. Wedge wire filter mesh - White steel slot screen mesh

Wedge wire screen is called Wedge wire screen in Vietnam in the field of mining coal, called white steel mesh screen , in the field of food processing and environmental wastewater treatment. called Triangular Filter Mesh or V-slot filter mesh . From the perspective of the only manufacturer in Vietnam, we call the product the wedge wire filter , this product has been registered with VinaScreen trademark and certified by the National Office of Intellectual Property - Ministry of Science and Technology.

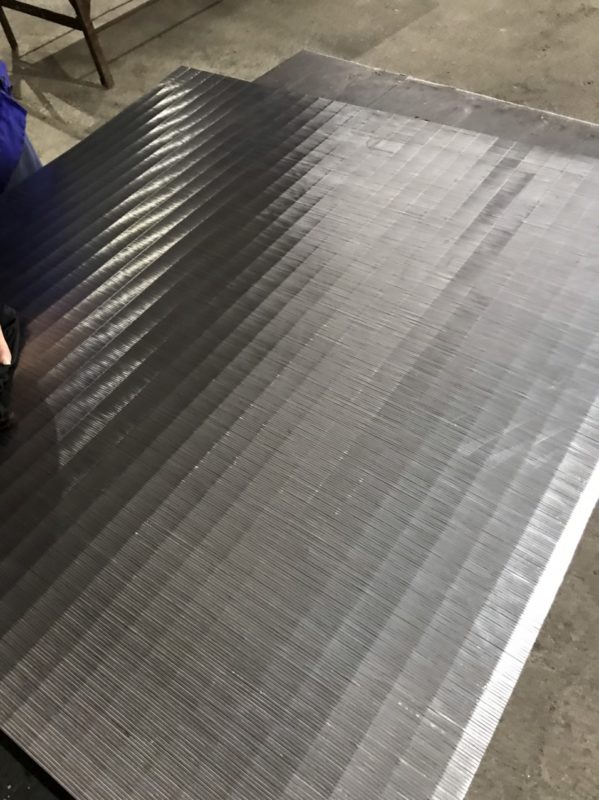

At present, we have 2 production lines of wedge wire filter with modern technology producing all kinds of filters from non-45mm to 1200mm and screen sizes up to 3200mm x 4000mm. Custom clearance from 0.15mm to 20mm with high accuracy (gap + -0.05mm). Providing for coal mining, food processing, environmental wastewater treatment, pulp recovery, water filtration, well drilling, oil refining ...

The wedge wire mesh material is SUS304 or SUS316L or SUS310 (heat resistant) as required.

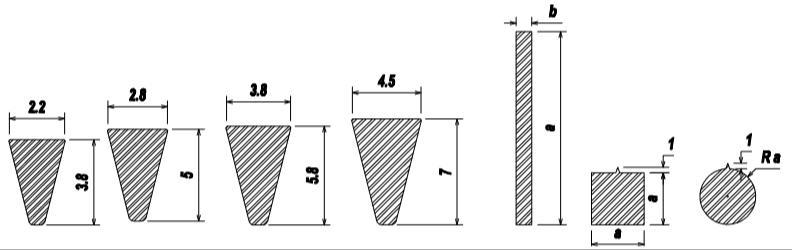

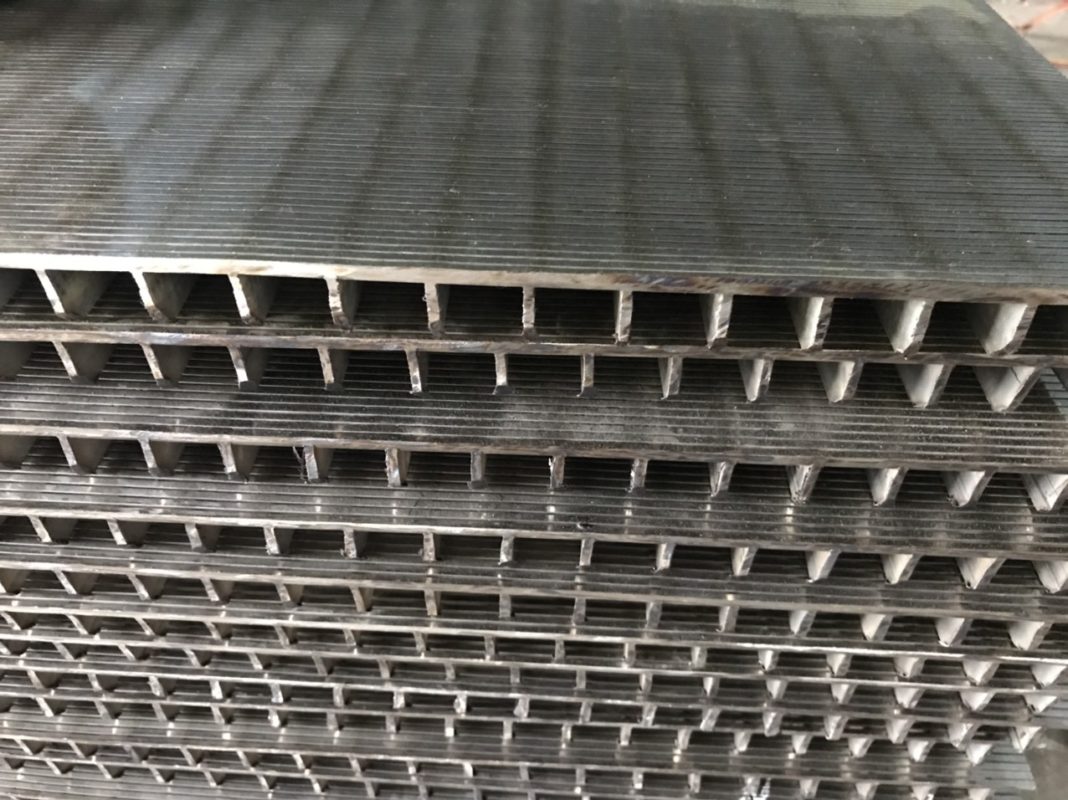

Structure of the net includes wedge wire and support bar:

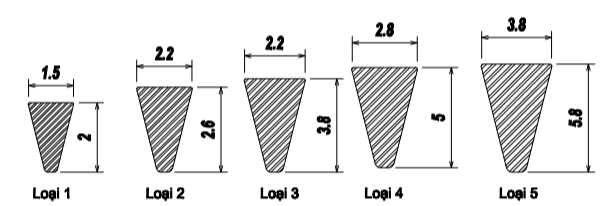

Wedge wire: is the mesh face wire has a triangular prism shape, advantages against clogging during use, we currently produce the following wedge wire types:

Support bar : is a bar with a rectangular shape (made up), a square, a triangle, a circle that hardens and shapes the grid, depending on the purpose of use to choose the shape and size of the support bar. fit.

The structure of VinaScreen wedge wire filter

.jpg)

Wedge wire and supporting bars are connected by short-welding method (spot welding, soldering) combined with solvent protection, the advantage of this method is not to change the chemical composition of the material to ensure the mechanical properties of material. Triangle filter mesh

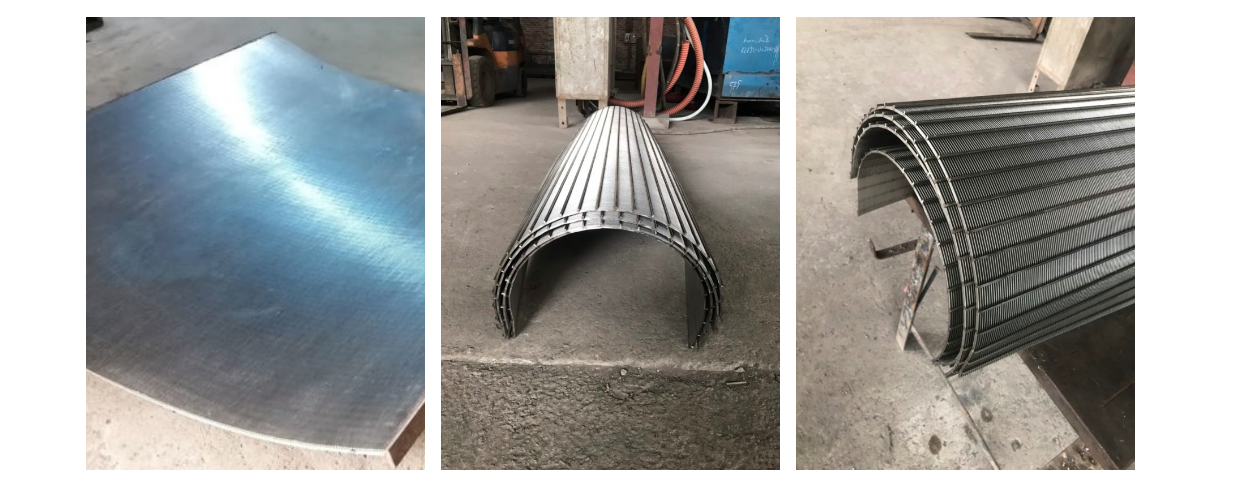

* VinaScreen flat wedge strainer (white steel sieve) with flat sheets of thickness from 2mm to 30mm, size (length * width) depends on customers' order requirements, mesh slot from 0.2-5.0mm. Application of washing coal, stone, sand sieve, chemical fertilizer sieve, filtering organic residue, making trash screens, static combs, treating environment ...

* VinaScreen sieve is tubular from 60mm to 1200mm, can have two end flanges, threaded joints or welded joints as required, mesh slots from 0.2 - 5.0mm. Leading application in the well technology in the world, the advantage of not deformation due to increased pressure, no clogging, no rust, extending the life of the well.

- There are two types of pipes divided according to the filter direction:

- + Afternoon filter from outside to inside: Application to empty the garbage separator; environmental waste water collection pipe, borehole filter tube, oil filter tube ... Triangle filter mesh

+ Dimension from inside to outside: Application of separating solid liquid, pulp filter, screw bag, organic waste (animal manure) ...

* VinaScreen centrifugal cone filter : Diameter from 400mm to 1650mm, solid structural frame, dynamic balance, high wear-resistant materials. Application to squeeze, separate water of granular products after cleaning dust, such as coal dust, exported sand, refined salt, sugar ...

VinaScreen curved shape filter net Solid liquid separation application, static garbage comb, pulp collection screening ...

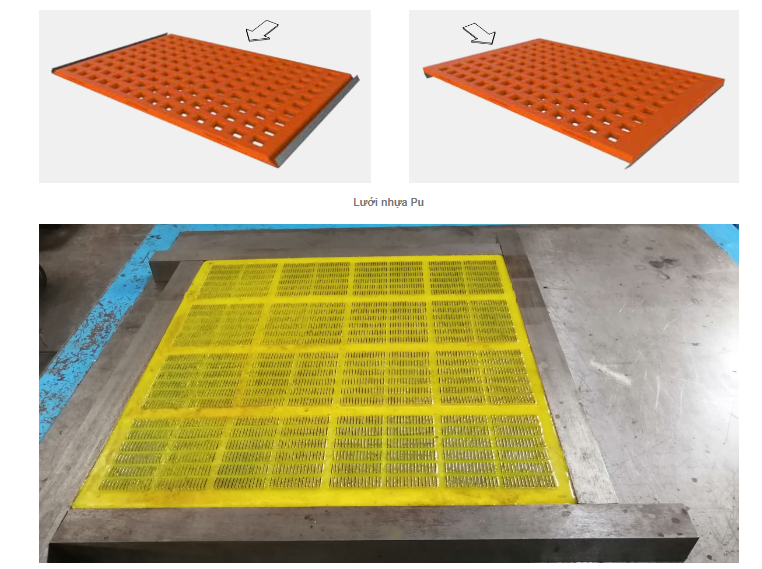

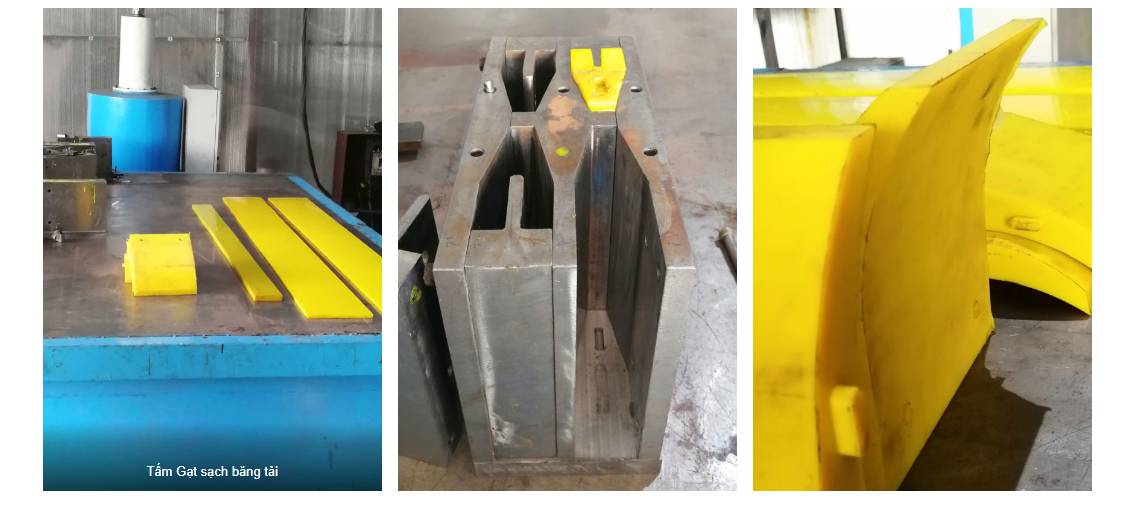

2. Pu (Polyurethane) products

Polyurethane plastic products are manufactured on modern technology with a system of quantitative mixers (the proportion of mixing components of CNC adjustment materials) with a pumping speed of 10 liters / minute.

3000x1500mm large table heat system meets product size requirements such as Pu plastic net, Pu plastic wiper plate

Raw materials for the production of Pu resin are primary polyurethane + vulcanized additives, materials originating from Australia and Japan, which have CO, CQ of the manufacturer. The hardness of Pu plastic for the net product and the blade to clean the conveyor belt is 80-85 shoreA, ensuring good elasticity and wear resistance.

Pu cake, support wheel Pu plastic

The hardness of Pu plastic for crust products is 95 shoreA, which ensures good load and abrasion resistance.

3. Production of industrial springs

Materials for manufacturing springs are elastic steel 60SiMnA, 60Mn, 60C2 ... from phi 16 to phi 36

Grinding two ends of the spring

Elastic steel billet making springs

4. Producing various kinds of woven screen mesh

5. Punching screen

The company would like to thank the trust of customers who have used the company's products over the years, we are always changing and developing, applying new and advanced technologies, modern equipment. To offer high quality products, competitive prices and reasonable services to serve customers. Best regards!